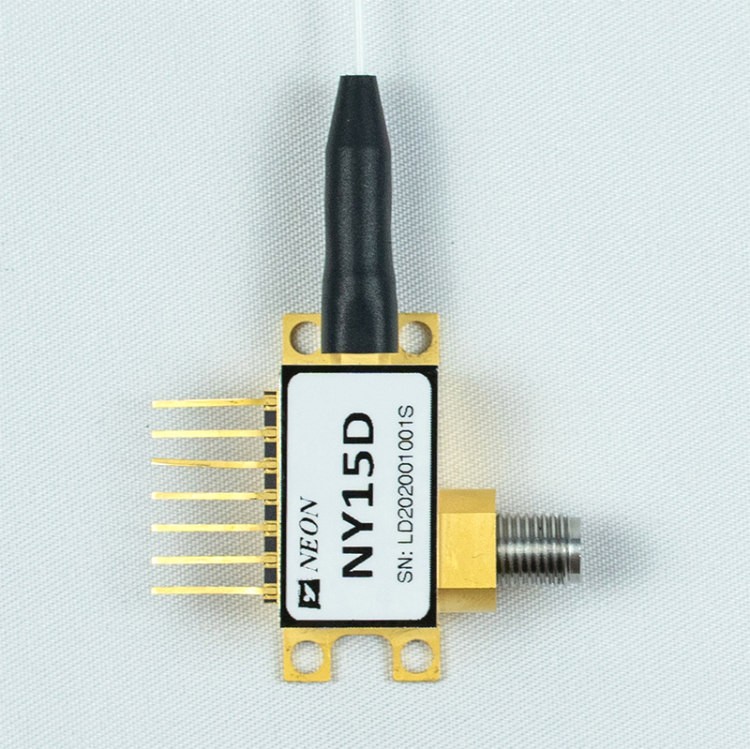

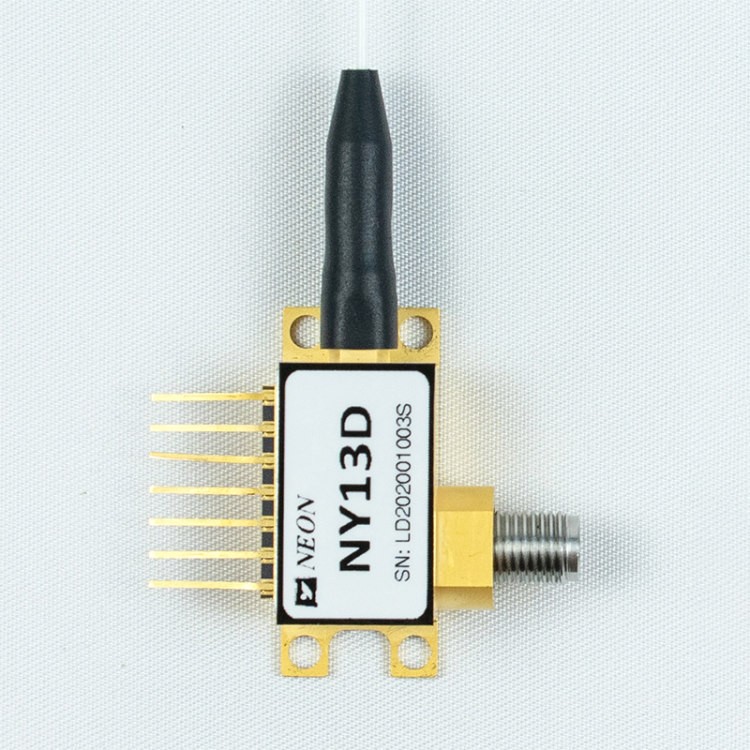

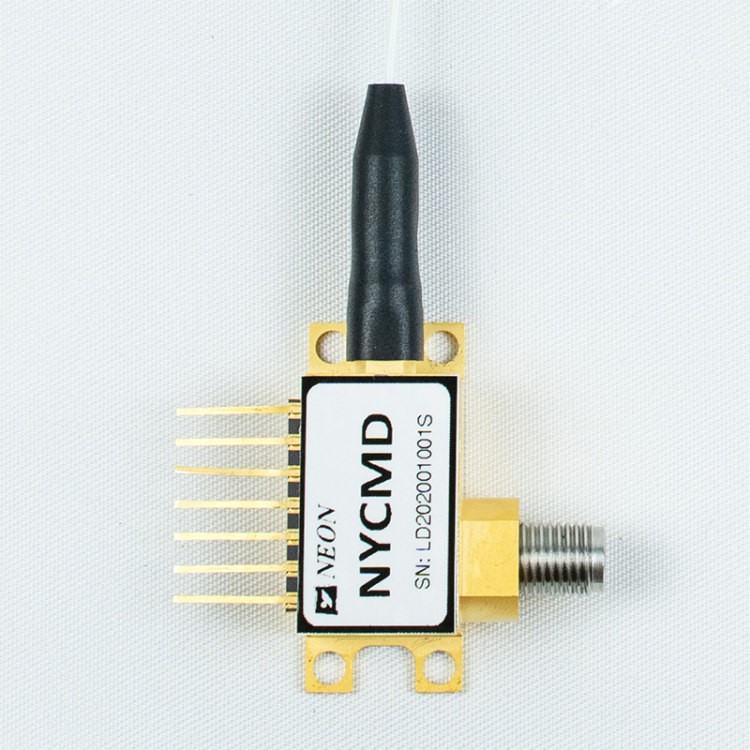

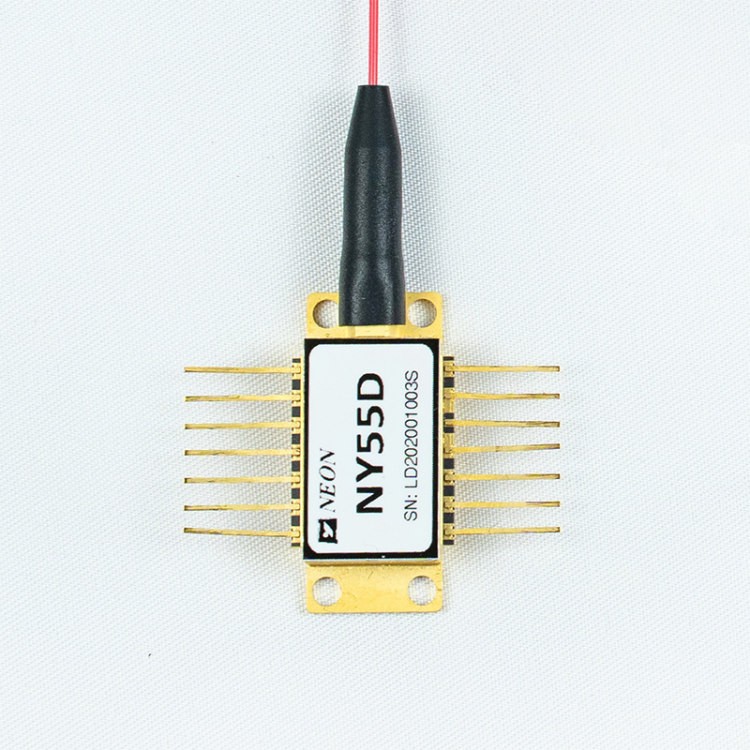

Protection Measures for Laser Diode Modules in High Dust Environments

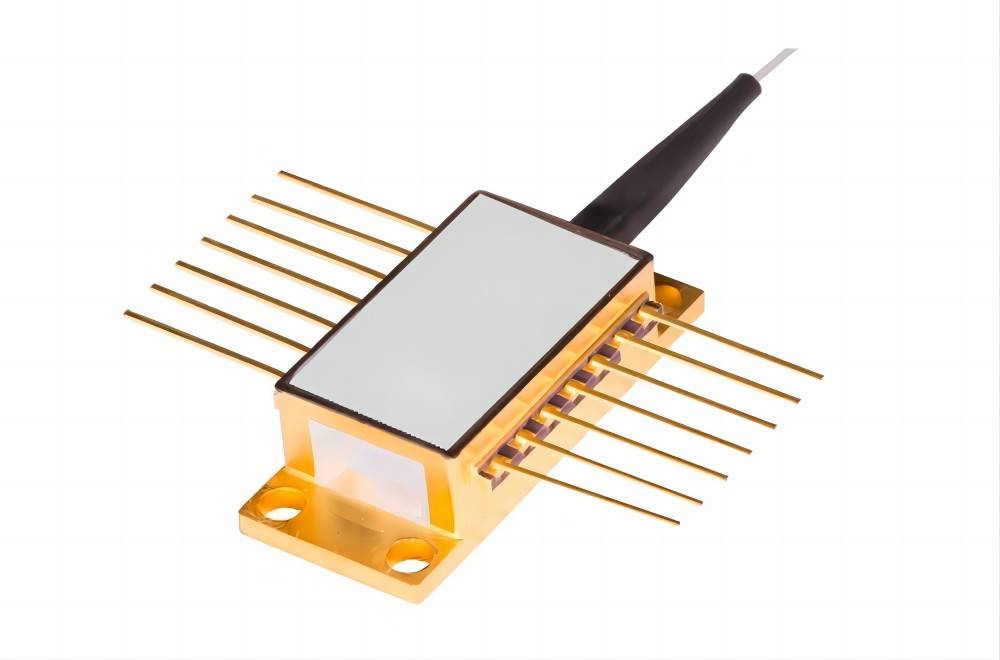

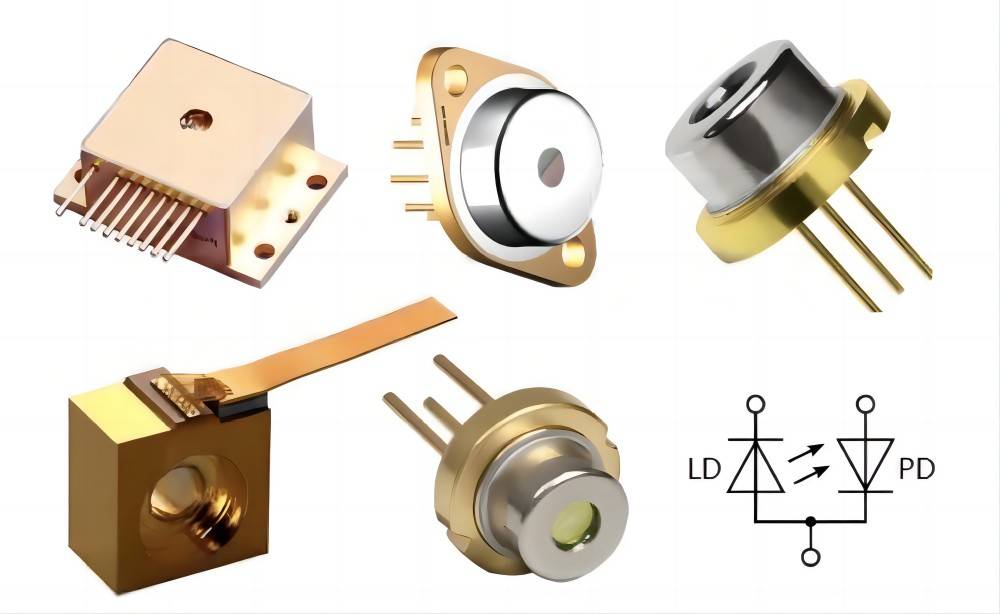

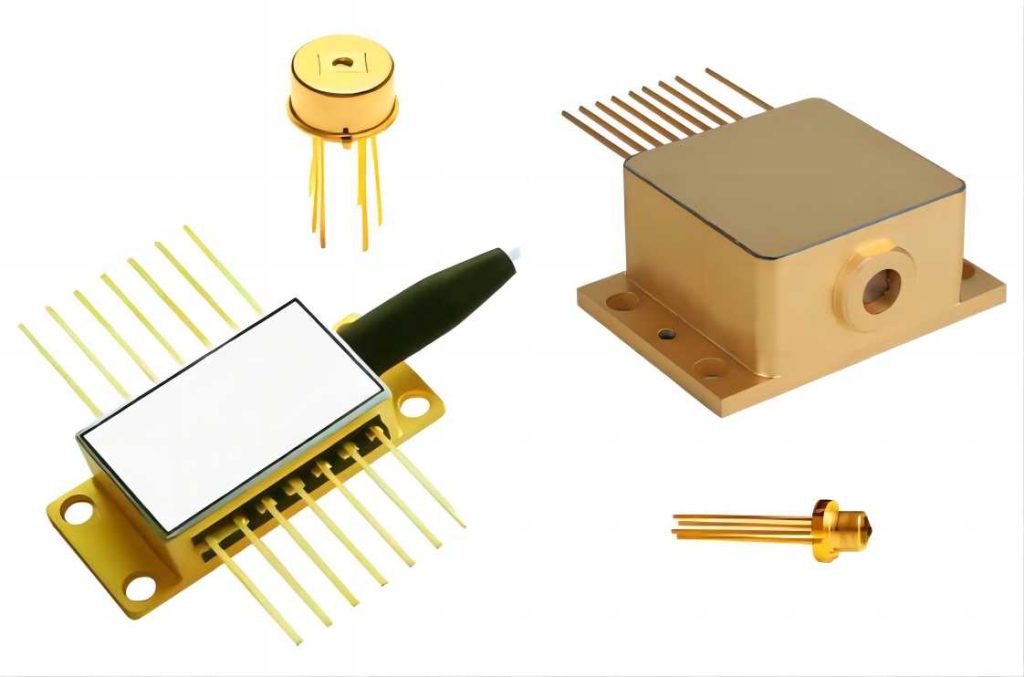

Laser diode modules offer a powerful and versatile light source for a wide range of applications. However, their performance and lifespan can be significantly impacted by harsh environments, particularly those with high dust concentrations. This article explores the key considerations and best practices for using laser diode modules in dusty environments, ensuring optimal performance and extending their service life.

How Does Dust Affect Laser Diode Modules?

Dust particles can wreak havoc on laser diode modules in several ways:

- Optical Degradation: Dust settling on the laser’s optical components, such as lenses and mirrors, can obstruct the light path, reducing output power and affecting beam quality. This can significantly hinder the laser’s ability to perform its designated tasks.

- Overheating: Dust accumulation can also act as an insulator, trapping heat within the module. This can lead to overheating, a major concern for high power laser diode modules. Excessive heat can damage the laser diode itself, shorten its lifespan, and decrease its overall performance.

Protective Measures for Laser Diode Modules in High Dust Environments

By implementing a combination of the following strategies, you can effectively mitigate the detrimental effects of dust on your laser diode module and ensure its continued operation:

1. Regular Cleaning and Protection

- Establish a routine cleaning schedule for your laser diode module, especially focusing on the optical components.

- Use high-purity, absolute ethanol or specialized cleaning solutions designed for optical components.

- Gently wipe the surfaces with absorbent cotton swabs, taking care to avoid scratching or damaging the delicate optics.

2. Efficient Heat Dissipation

- Heat sinks play a vital role in drawing heat away from the laser diode, preventing overheating. Ensure proper selection and installation of heat sinks that are compatible with your specific module.

- Utilize high-performance thermal interface materials (TIMs) to bridge the gap between the laser diode and the heat sink. These materials efficiently transfer heat, ensuring optimal thermal management.

3. Optimized Optical Design

During the design phase of the laser diode module, careful consideration should be given to the optical components, such as collimating lenses and micro-optics. These elements significantly impact the beam quality and output power of the laser. Selecting high-quality optics that are less susceptible to dust contamination is crucial.

4. Precise Electronic Control and Cooling

A well-designed electronic control system can optimize the driving efficiency and stability of the laser diode. This translates to improved performance and potentially reduced heat generation.

Implementing an effective cooling system, such as a fan or a chilled water circulation loop, is essential for maintaining a suitable operating temperature for the laser diode. This helps to counteract the heat generated during operation and further minimizes the negative effects of dust accumulation.

5. Environmental Adaptability Considerations

The laser diode module’s ability to adapt to various environmental conditions, including temperature, humidity, and dust levels, is a critical factor for its performance. Choosing a module designed for the specific operating environment you anticipate is vital.

6. Detailed Maintenance Records and Scheduled Maintenance

Establish a maintenance schedule tailored to the specific operating conditions and the characteristics of your laser diode module. Regularly cleaning the module and inspecting for dust buildup are essential practices.

Maintain meticulous records of all maintenance activities, including the date, personnel involved, type of maintenance performed, and any observations or notes. This detailed documentation facilitates tracking the maintenance history and evaluating the effectiveness of your strategies.

7. Prompt Troubleshooting and Repair

Should you encounter any issues with your laser diode module, such as a drop in output power, wavelength shifts, or beam instability, prompt troubleshooting and repair are essential. These problems can often be attributed to dust contamination, and addressing them swiftly can minimize downtime and ensure continued optimal performance.

8. Professional Repair and Replacement

For repairs or replacements that require specialized knowledge or equipment, enlist the services of qualified technicians. They possess the expertise to handle laser diode modules safely and effectively, adhering to all safety protocols and operational specifications. This ensures proper repair or replacement and minimizes the risk of further damage.

9. Dust Protection for High-Dust Environments

For applications in particularly dusty environments, consider employing additional dust protection measures. These may include:

- Dust-proof connection structures: These enclosures prevent dust from entering the laser transmitter head, safeguarding the lens and extending the operational lifespan of the module.

- Dust-proof plugs: When the laser is not in use, utilizing dust-proof plugs on the module’s connectors provides an extra layer of protection against dust infiltration.

Conclusion

By adopting a comprehensive approach that incorporates regular cleaning, efficient heat dissipation, optimized optical design, precise electronic control and cooling, and meticulous maintenance practices, you can effectively safeguard your laser diode module from the detrimental effects of dust, even in harsh environments. Remember, employing dust protection measures specifically designed for high-dust environments, such as dust-proof connection structures and plugs, further enhances protection and extends the operational lifespan of your laser diode module. Additionally, for high power laser diode modules, where heat management is even more critical, implementing these strategies becomes even more important to ensure reliable and consistent performance. By adhering to these guidelines and remaining vigilant about dust mitigation strategies, you can ensure that your laser diode module continues to deliver optimal performance for years to come.

Remember, consulting with laser diode module manufacturers or experienced professionals familiar with your specific application is always recommended. They can provide valuable insights and tailored recommendations to ensure you select the most suitable module and implement the most effective dust protection strategies for your unique needs.