What are the Main Elements of An Optical Transmitter?

As the development of optical communication technology continues, optical transmitters are now part of the vital components of the modern communication system.

From high-speed connections in data centers to precise signal transmission in medical devices, optical transmitters are involved.

So, what are the main elements of an optical transmitter?

In this article, we will introduce to you a comprehensive overview of its key components and working principles and offer guidance on how to choose the right product to meet the needs of different application environments.

Part 1. What is an Optical Transmitter?

An optical transmitter is a crucial device used in fiber optic communication systems. Its primary function is to convert electrical signals into optical signals

It involves modulating electronic system data and transforming it into light pulses using a laser or LED, and sending the pulses through the optical fibers to the destination.

The transmitter efficiency directly adds up to the speed, stability, and transmission distance of the overall optical communication link and is therefore one of the building blocks of modern communication systems.

Part 2. Why Understanding Components of Optical Transmitter Matter?

Knowledge of an optical transmitter’s internal components is critical to creating efficient, effective, and high-performing communication systems. When creating new equipment or maintaining existing networks, knowing what each component does provides more decision-making authority, reduces risks, and enhances overall system performance.

Optimized Integration and Interoperability

With a thorough knowledge of every module’s operations, one can effortlessly combine them with other pieces of machinery, reducing the probability of a system clash or wastage of resources.

Optimized System Reliability

Understanding how each module operates guarantees seamless integration with other hardware components and minimizes the risk of system conflicts or inefficiency.

Improved System Reliability

Unambiguous understanding of component interactions means faster troubleshooting and maintenance, less failure, and more reliable performance.

Improved Efficiency and Lower Costs

Inelligent part choice leads to reduced energy consumption, improved thermal efficiency, and savings on operating expenses over the long term.

Part 3. Main Elements of An Optical Transmitter

An optical transmitter comprises several primary components that work in concert to transform electrical signals into stable high-speed light signals. Each module plays an essential part in maintaining performance, signal integrity and energy efficiency – here’s a detailed look at them all:

1. Laser Diode Source

Laser diodes form the core of any optical transmitter and generate an optical carrier signal, as seen with such popular examples as:

DFB (Distributed Feedback) Laser: These lasers offer extremely precise wavelength stability, making them suitable for long distance transmission of high precision optical information.

VCSEL (Vertical-Cavity Surface-Emitting Laser): These small form factor lasers have become popular solutions for short range high-speed communication applications such as data center environments. They offer both affordability and portability.

DML (Direct Modulation Laser): Small and easy to integrate, DML is suitable for small form factor modules with medium speed use cases.

The type of laser affects modulation speed directly, wavelength accuracy, output power and thermal stability – for instance DFB lasers are commonly found in telecom networks while VCSELs can be found in high-volume data center deployments.

2. Optical Modulator

The optical modulator is imposing the electrical data signal onto the light wave. It may be employed in two main ways:

Direct Modulation: It involves modulating the drive current of the laser to encode the data. It is simpler and less expensive to implement but adds chirp and degradation of the signal at high rates.

External Modulation: Uses an independent source—an MZM, for instance—to modulate the continuous-wave laser light. It yields improved performance at lower jitter, greater fidelity, and greater control at high frequencies.

External modulators are normally used in long-haul, coherent, and advanced modulation format systems.

3. Driver Circuitry

The driver circuit supplies the laser diode or the modulator with the required current or voltage and controls parameters like:

- Modulation rate

- Signal amplitude

- Pulse shape and timing

It is required to have good driver circuits in order to maintain low bit error rates (BER), signal integrity, and high-speed data rates. Pre-emphasis or equalization techniques are used in certain high-end drivers to fight signal degradation at longer links.

4. Encoding & Control Logic

This module offers digital signal preprocessing before optical transmission. Its function typically includes:

Data Encoding: Using formats such as NRZ (Non-Return-to-Zero), PAM4 (Pulse Amplitude Modulation), or others depending on speed and use.

Clock Data Recovery (CDR): Ensures synchronization between transmit and receive.

Thermal Management: Thermal management involves closely tracking internal temperatures to protect sensitive components.

Automatic Power Control (APC): Maintains optical output power at safe and stable levels for optical equipment.

Modern optical transmitters typically incorporate this logic into a small system-on-chip (SoC), to optimize performance, power conservation and integration.

5. Optical Interface

The optical interface ensures a robust and efficient coupling of the laser output into the optical fiber. It consists of features such as:

Optical connectors (e.g., LC, SC, MPO): Provide physical connection points with minimal insertion loss.

Couplers or lenses: Concentrate light from the laser into the fiber with high precision.

Alignment and packaging structures: Supply mechanical toughness and optical alignment under thermal or vibration excitations.

A proper optical interface is a must for loss reduction, stable power supply, and maintenance of long-term system reliability.

6. Optional Expansion Components

Depending on the specific application requirement, some optical transmitters have extra functional modules to enhance performance, stability, and integration ease. Some typical optional components are:

Temperature Control Module (e.g., TEC Cooler)

A Thermoelectric Cooler (TEC) can be used to maintain a constant temperature for the laser diode, locking the emission wavelength in place and otherwise improving performance in varying environmental conditions.

Optical Amplifier

Amplifiers are used to boost optical power output, especially in long-distance transmission where signal loss is to be minimized. Amplifiers find common usage in backbone networks and metro-area communications systems.

Integrated Modules (e.g., TOSA – Transmitter Optical Sub-Assembly)

A TOSA is a combined module packaging significant components such as the laser diode, modulator, and optical interface in a single sealed package. This configuration facilitates easier assembly, enables rapid deployment, and makes it easier to replace in the field.

Part 4. Applications of Optical Transmitters

Optical transmitters are a part of numerous markets where stable, high-speed data transmission is of utmost significance. Prominent application areas are:

Telecommunication Networks

Optic transmitters play a pivotal role in creating high-capacity telecom infrastructure. From base station connections and long-distance fiber networks to FTTH solutions, optical transmitters enable reliable delivery of broadband services both to urban users and rural dwellers alike.

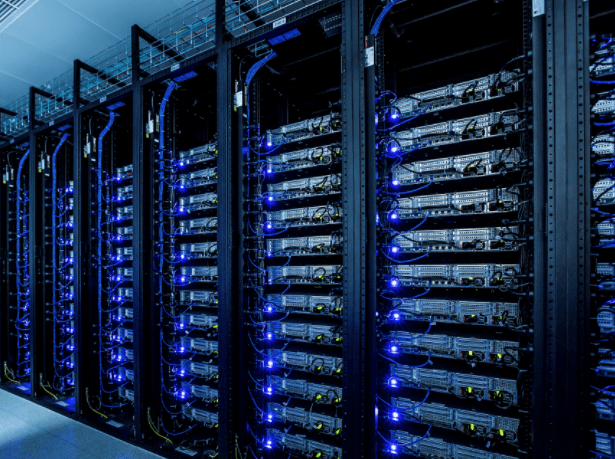

Data Centers

With the rapid proliferation of 400G and 800G optical interconnects, optical transmitters have become critical components in supporting high data rates and low latency data exchange between servers, switches and storage arrays in hyperscale data centers. Their performance directly affects their scalability and energy efficiency.

Medical Devices

In advanced healthcare systems, such as high-resolution imaging, scanning diagnostics, and real-time surgical monitoring equipment, optical transmitters are used to transmit large volumes of sensor or image data with ultra-low latency and high accuracy to provide exact diagnostics and quick response.

Industrial Control Systems

Optical transmitters enhance the quality of remote monitoring and control systems with high immunity to electromagnetic interference (EMI). They are thus optimally designed for extreme industrial environments such as oil & gas fields, power substations, and production lines.

Neon Optical Transmitters

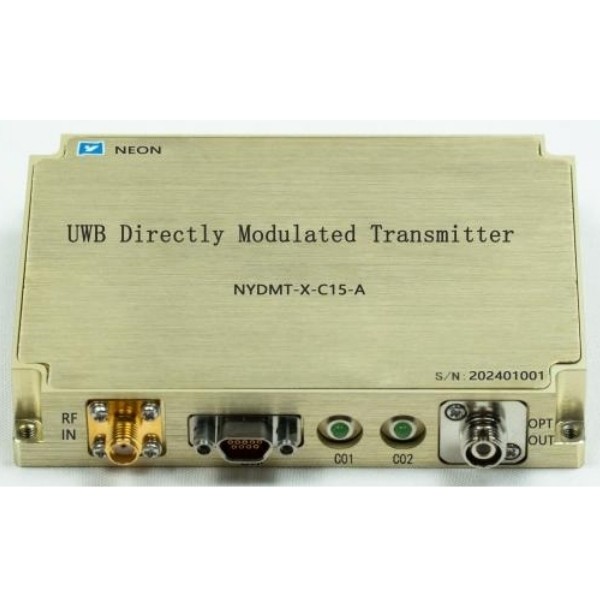

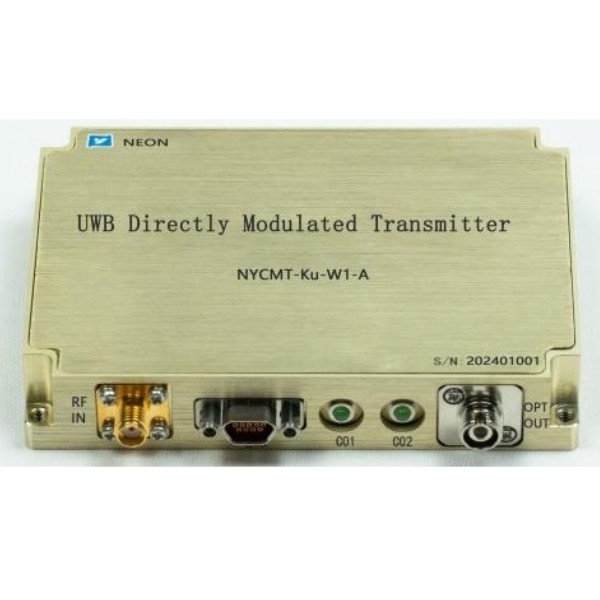

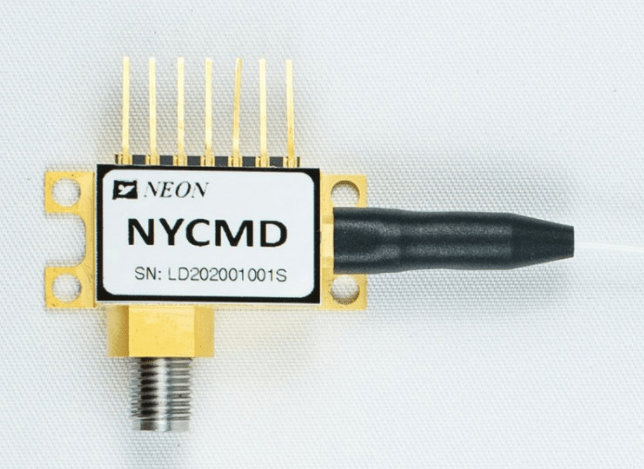

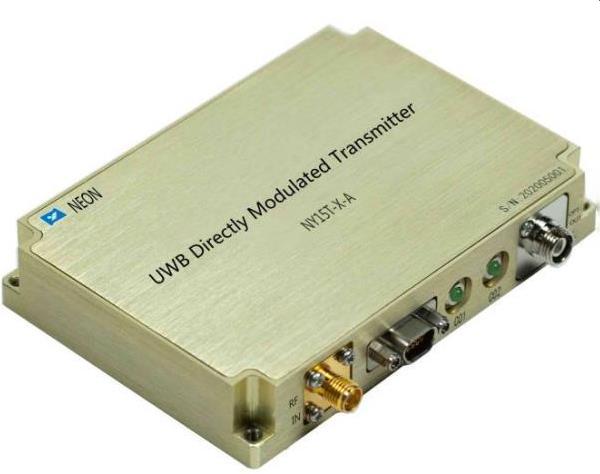

As a leading supplier of high-quality optical transmitters, NEON offers a wide range of products, including digital optical transceivers, Mini UWB transmitter modules, and Directly Modulated Lasers (DML).

Our receivers are designed for high bandwidth, low power, and high integration—ideal for telecom, data centers, and precision medical devices. From rugged long-haul networks to compact medical systems, NEON delivers reliable optical solutions.

Part 5. How to Select the Proper Optical Transmitter?

It is of utmost importance for an organization’s optimal system performance, longevity, and seamless integration to meticulously select the optical transmitter. The following factors are of vital importance when determining and purchasing the optical transmitter:

Data Rate & Modulation Format

Evaluate whether the transmitter can support the intended data transmission speed (e.g., 10G, 100G, 400G) and modulation type (e.g., NRZ, PAM4, or coherent modulation). Different applications—e.g., long-haul backbones or inter-data center interconnects—may demand different combinations of speed and modulation for compatibility and performance.

Laser Type & Wavelength Stability

Choose a laser source (e.g., DFB, VCSEL, or DML) suited to the transmission length and wavelength precision required.

For instance:

- VCSELs are best suited for short-reach, high-density use cases.

- DFB lasers offer better wavelength stability, which is particularly useful for temperature-sensitive or long-haul applications.

Consider if the transmitter supports temperature compensation features like TEC to operate under fluctuating environmental conditions.

Interface & Packaging Type

Examine the physical form factor and optical/electrical interfaces for seamless integration into your system. Key considerations are:

- Connector types (e.g., LC, SC, MPO)

- Electrical interfaces (e.g., SFP+, QSFP, or custom boards)

- Whether the packaging meets mechanical and thermal requirements for your deployment scenario

Compact, integrated modules like TOSA can enable simpler installation and maintenance, especially in high-density environments.

Brand Reputation & Technical Support

A reliable supplier not only offers superior products but also support throughout the entire life cycle, including:

- Timely technical documentation (e.g., data sheets, integration guides)

- Firmware/software updates (for digital modules)

- Effective after-sales support

Choosing a vendor with deep industry experience and robust R&D depth ensures smoother integration and long-term dependability.

Conclusion: Why Choose NEON as Your Optical Transmitter Partner

Selecting the right optical transmitter isn’t just a question of technical standards compliance, it’s a question of building a sound, expandable base for your communication system. With many years of expertise in high-speed UWB optical transmission, NEON provides products that combine speed, stability, and efficiency in telecommunication, data center, and healthcare industries.

Our product lineup includes DML laser modules, Mini UWB transmitters, and high-speed digital optical transceivers, all of which are intended to be compact, low power, and able to meet high bandwidths. As part of the hardware, NEON must also provide:

- Comprehensive technical documentation and integration manuals

- Product support customized to your application needs

- Worldwide shipping and effective after-sales support

- Assurance of continuous innovation and long-term collaboration

From the creation of next-gen fiber networks to the upgrading of high-accuracy medical equipment, NEON is your go-to partner for optical transmission solutions that perform today and tomorrow.nd high-performance technology solutions to support them.