Ordinary Light-Emitting Diode VS DFB Laser Diode

The physical structure of the laser diode is to place a layer of optically active semiconductor between the junction of the light-emitting diode, and its end surface has a partial reflection function after being polished, thus forming an optical resonant cavity. In the case of forwarding bias, the LED junction emits light and interacts with the optical resonant cavity to further stimulate the emission of single-wavelength light from the junction. The physical properties of this light are related to the material. And ordinary light-emitting diodes are LEDs.

So what is the difference between an Ordinary light-emitting diode and a Distributed Feedback Lasers (DFB) laser diode? We will distinguish between them in terms of their principles and effectiveness.

The difference in the principle of light emission

LED uses the spontaneous emission of carriers injected into the active region to recombine light, while LD is recombined light-emitting by stimulated radiation. The direction and phase of the photons emitted by the light-emitting diode are random, and the photons emitted by the laser diode are in the same direction and the same phase.

LED is the abbreviation of Light Emitting Diode. It is widely seen in daily life, such as indicator lights of household appliances, anti-fog lights on the rear of automobiles, etc. The most notable feature of LED is its long service life and high photoelectric conversion efficiency. The reason is that in the PN junction of some semiconductor materials, the injected minority carriers and majority carriers will release the excess energy in the form of light when they recombine, thereby directly converting electrical energy into light energy. With reverse voltage applied to the PN junction, it is difficult to inject minority carriers, so it does not emit light. This kind of diode made by injection electroluminescence principle is called a light-emitting diode, commonly known as LED.

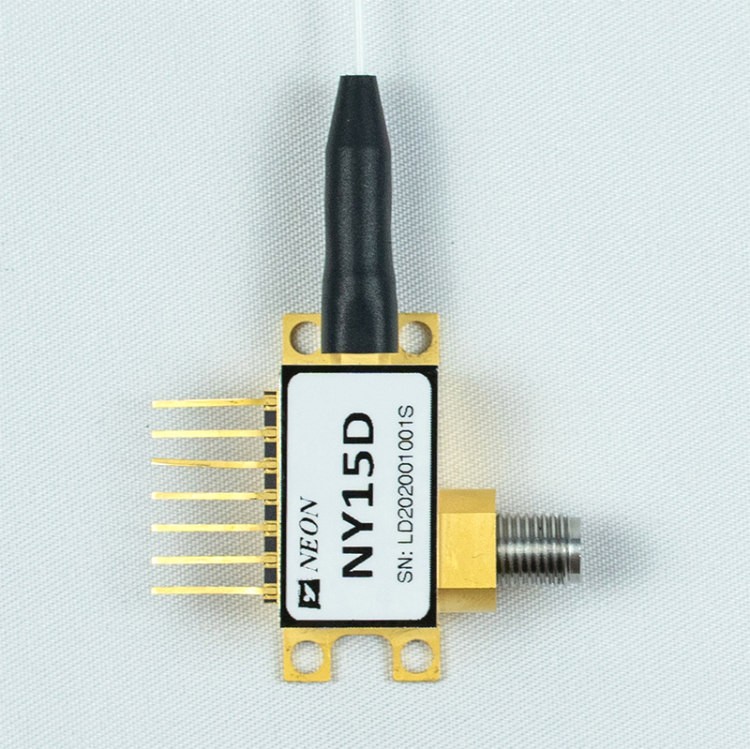

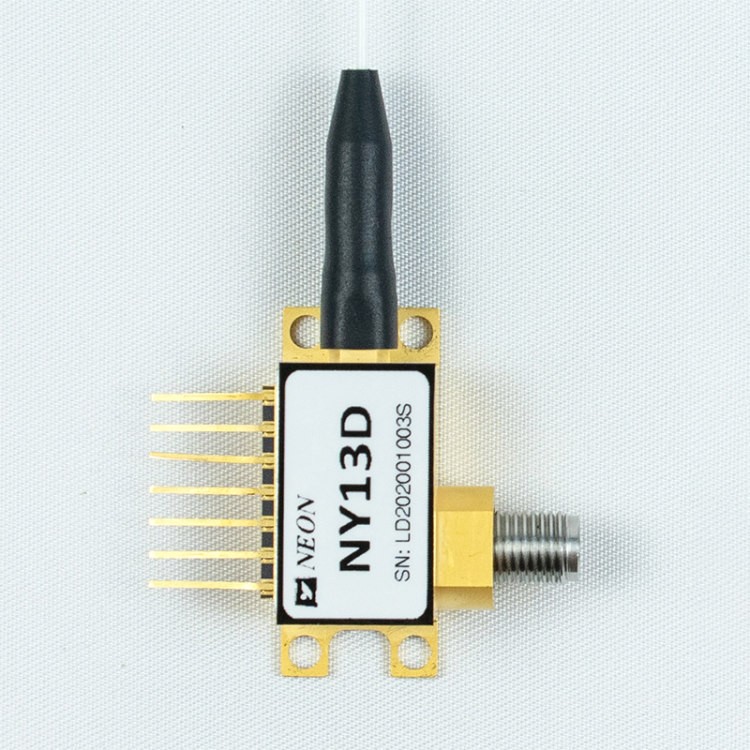

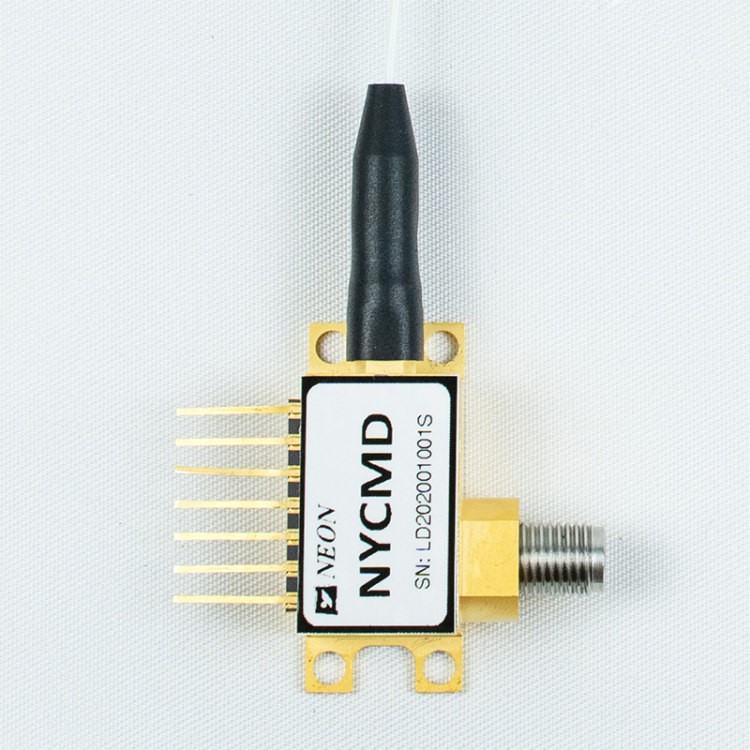

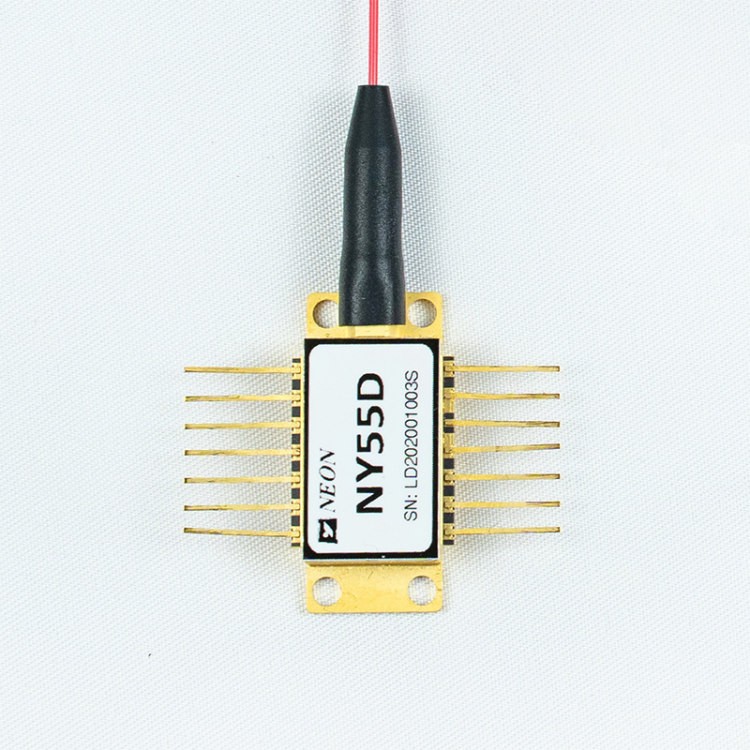

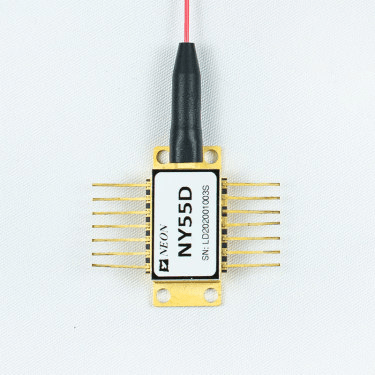

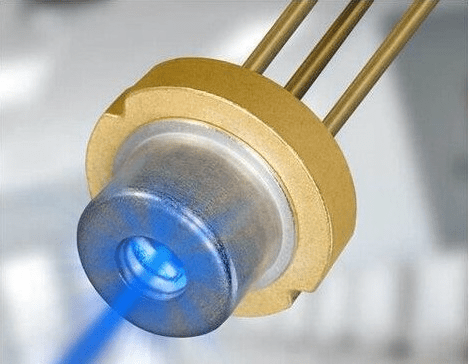

DFB LD is the English abbreviation of the dfb laser diode. The physical structure of laser diode is to place a layer of optically active semiconductor between the junctions of the light-emitting diode, and its end surface has a partial reflection function after being polished, thus forming an optical resonant cavity. In the case of forwarding bias, the LED junction emits light and interacts with the optical resonant cavity to further stimulate the emission of single-wavelength light from the junction. The physical properties of this light are related to the material. The working principle of a semiconductor laser diode is theoretically the same as that of a gas laser. Laser diodes are widely used in low-power optoelectronic devices such as CD drives in computers and print heads in laser printers.

As a new technology of laser diodes, DFB laser diodes have now replaced traditional laser diodes and become a new trend.

The difference in principle, structure, and efficiency between ordinary light-emitting diodes and DFB laser diodes

1) The difference in the working principle: LED uses the spontaneous emission of carriers injected into the active area to recombine light, while DFB laser diodes recombine light by stimulated radiation.

(2) The difference in architecture: DFB laser diode has an optical resonant cavity so that the generated photons oscillate and amplify in the cavity, while LED does not have a resonant cavity.

(3) The difference in efficiency: LED has no critical value characteristics, the spectral density is several orders of magnitude higher than that of DFB laser diodes, the output light power of the LED is small, and the divergence angle is large.

In general, the difference between ordinary light-emitting diodes and laser diodes lies in the difference in diode architecture and efficiency. If you have any questions about DFB laser diodes or you need a reliable laser diode supplier, you can consult us. Our engineers can give you a complete solution.