How to Distinguish and Choose Between EML and DML Lasers?

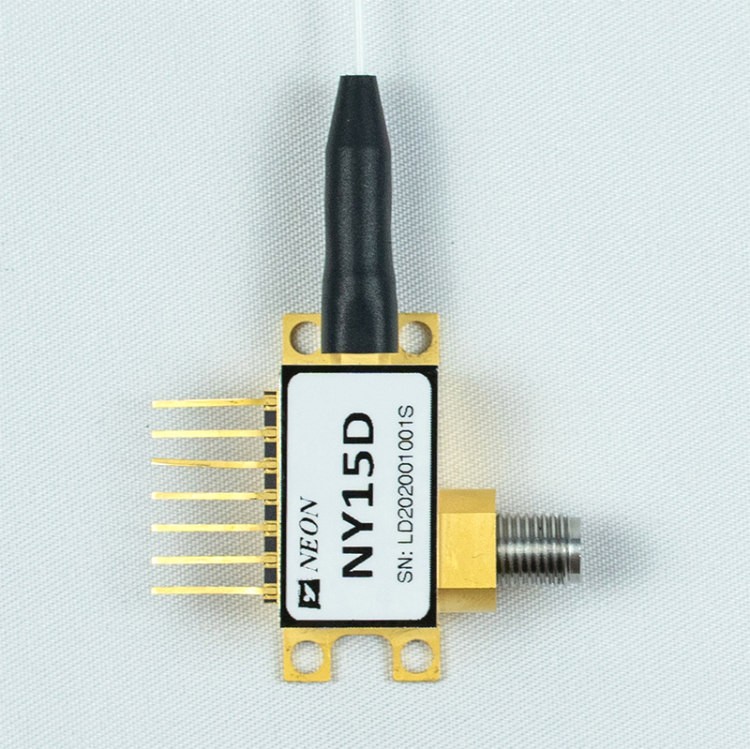

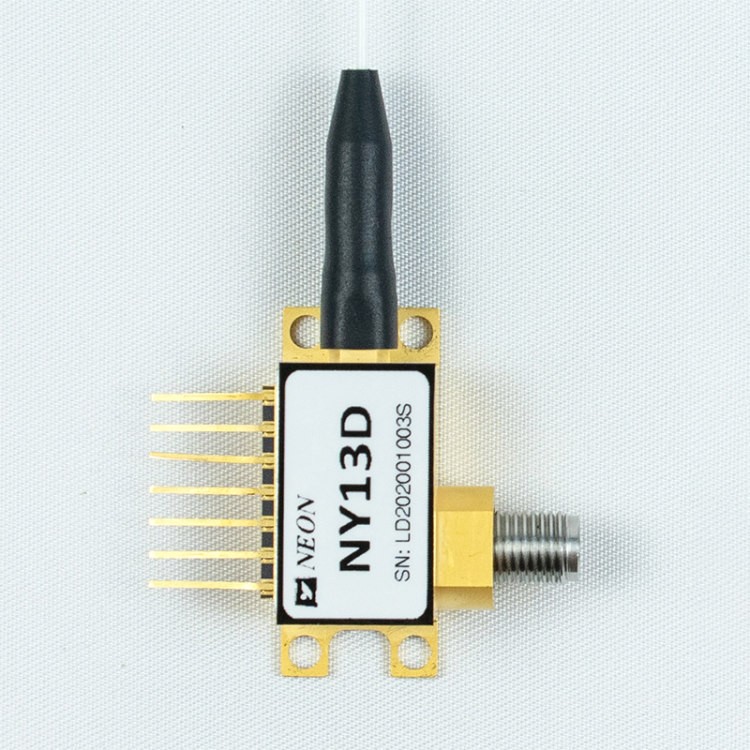

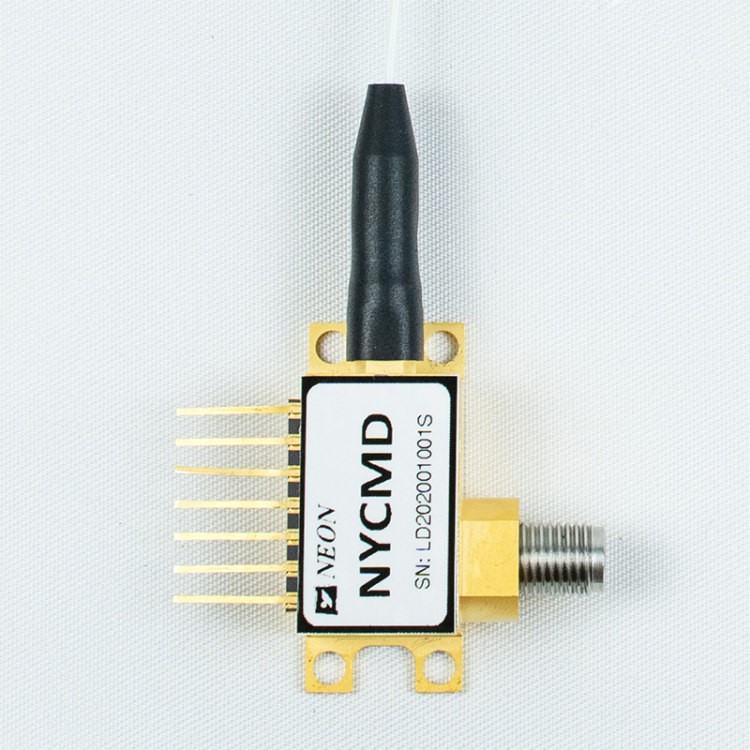

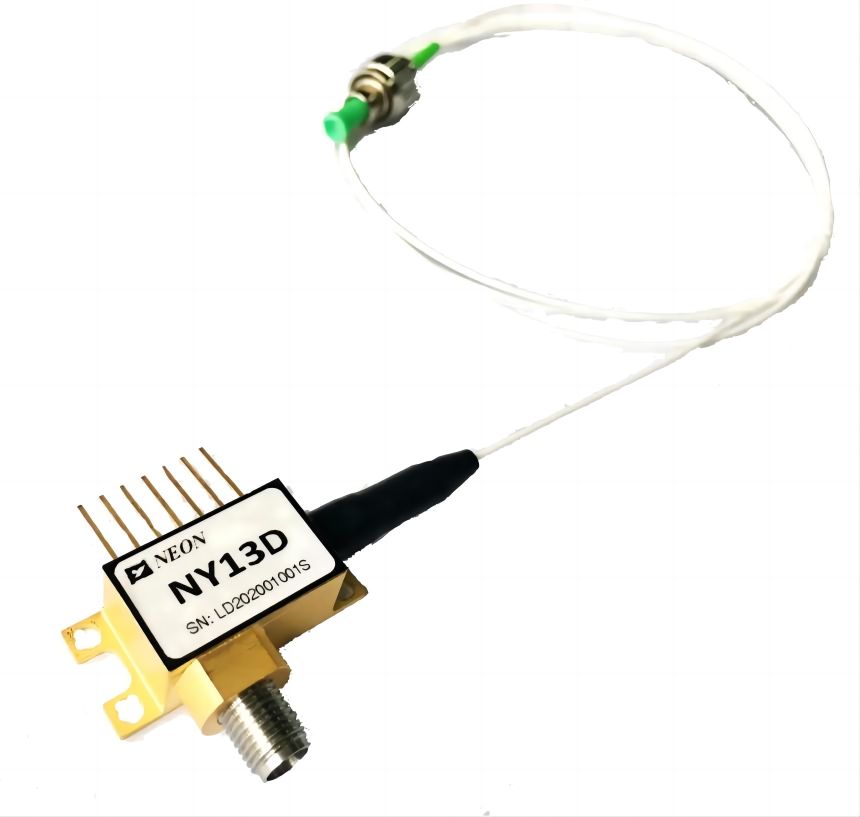

EML (External Cavity Laser) and DML (Directly Modulated Laser) are two types of lasers that play important roles in optical modules for optical communication and other photonic applications. In this article, we will follow NEON Photonics to learn about their applications in optical modules.

What Are EML and DML Lasers?

EML lasers, also known as optically modulated lasers, work on the principle of photoelectric effect. They modulate the amplitude and phase of the laser by applying a voltage to the semiconductor material, thus realizing high-speed optical modulation. EML lasers have the advantages of high speed, high efficiency, and low noise, and are widely used in optical fiber communication, optical imaging, and optical sensing.

DML lasers, also known as directly modulated lasers, work on the principle of carrier concentration changes in the semiconductor material to modulate the amplitude and phase of the laser. By directly modulating the laser, you can quickly control and adjust the laser. DML lasers have the advantages of low cost, low power consumption, and easy integration, and are widely used in optical fiber communication, optical computing, and optical sensing.

How to Distinguish and Select Between EML and DML Lasers

Choosing between EML and DML lasers demands a nuanced understanding of their respective strengths and weaknesses. While their basic functions overlap, their technical nuances can significantly impact your application. Let’s delve deeper into the key factors to consider:

Understand the factors that determine the type of laser

- EML laser: These lasers employ an external modulator, often a Mach-Zehnder modulator, to control the light output. This allows for high-speed modulation (up to 100 Gbps) and precise control over the light’s amplitude and phase. However, it adds complexity and cost to the overall system.

- DML laser: These lasers directly modulate the laser diode, resulting in simpler and more cost-effective designs. However, this direct modulation limits their modulation speed (typically below 10 Gbps) and introduces chirp (changes in wavelength during modulation), which can degrade signal quality over long distances.

Understand the spectral range of the laser

- EML laser: Due to the external modulator, EML lasers offer a narrower spectral linewidth, ideal for dense wavelength division multiplexing (DWDM) systems. This allows for packing more data channels into a single fiber optic cable.

- DML laser: Their direct modulation results in a wider spectral linewidth, making them less suitable for DWDM applications. However, their broader spectrum can be advantageous in short-distance links where spectral efficiency is less critical.

Understand the working speed of the laser

- EML laser: The external modulator adds power consumption, making EML lasers slightly less power efficient than DMLs. However, their precise control over light output can compensate for this in some applications.

- DM L Laser: Their simpler design translates to higher power efficiency and lower cost. However, their higher power output can introduce thermal issues in some situations.

Understand the application scenarios of the laser

- EML lasers can emit a stable and narrow spectrum as the light source of DWDM (dense wavelength division multiplexing) systems, allowing them to transmit a large number of data streams and achieve high-speed optical communication. EML’s tunability allows for a flexible selection of different wavelengths in optical communication systems, increasing the utilization of optical fibers and the efficiency of data transmission.

- DML lasers are typically used for short-distance optical communication transmission. Although their output spectrum is relatively wide, they still have advantages in some low-speed data transmission and short-distance communication.

Conclusion

Choosing between EML and DML lasers depends on a careful balance of factors like modulation speed, spectral purity, power efficiency, cost, and application requirements. By understanding the nuances of each type, you can make an informed decision that optimizes your system performance and cost-effectiveness. Remember, consulting with a qualified optical engineer can provide valuable insights and ensure you choose the best laser for your specific needs.