High Power Laser Diodes and Arrays: A Powerful Tool for a Variety of Applications

High power laser diodes and arrays are a type of semiconductor laser that can emit a beam of coherent light with a power output of watts. They are used in a variety of applications, including laser cutting, laser welding, and laser marking.

In this article, we will discuss the basics of high power laser diodes and arrays, as well as their applications. We will also compare high power laser diodes and arrays, and discuss the factors to consider when choosing between the two devices.

How High Power Laser Diodes Work?

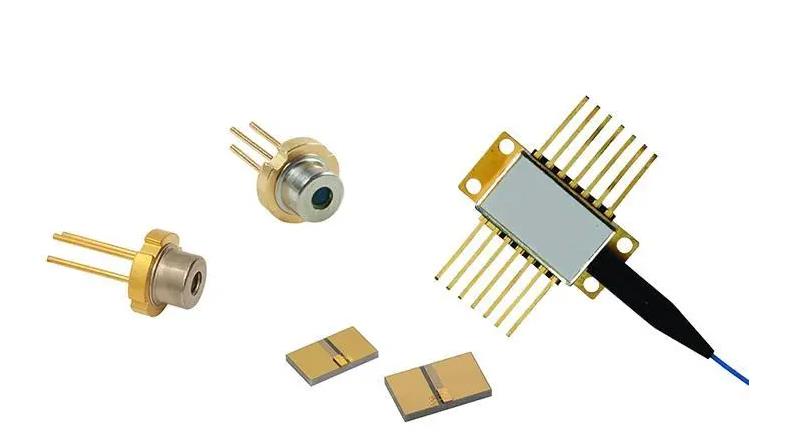

A high power laser diode is made up of two semiconductor layers, a P-type layer and an N-type layer. These layers are doped with different elements, such as gallium arsenide, to create a region where light can be amplified. When a current is applied to the diode, electrons are excited from the P-type layer to the N-type layer. As the electrons recombine, they emit photons of light.

The power output of a high power laser diode can be increased by stacking multiple diodes together. This is called a laser diode array. Laser diode arrays are typically used in applications where a high power laser beam is needed, such as laser welding and laser cutting.

What Are High Power Laser Diode Arrays?

A high power laser diode array is a group of high power laser diodes that are mounted together on a single substrate. The diodes in an array are typically arranged in a line or a matrix. This allows the array to emit a single beam or multiple beams.

The power output of a high power laser diode array can be increased by increasing the number of diodes in the array. For example, a 10-watt laser diode can be combined with nine other 10-watt laser diodes to create a 100-watt laser diode array.

Applications of High Power Laser Diodes and Arrays

High power laser diodes and arrays are used in a variety of applications, including:

- Laser cutting: High power laser diodes and arrays are used to cut a wide variety of materials, including metal, plastic, and wood. Laser cutting is a process that uses a laser beam to vaporize or melt material, allowing it to be cut to a precise shape.

- Laser welding: High power laser diodes and arrays are used to weld a wide variety of materials, including metal, plastic, and glass. Laser welding is a process that uses a laser beam to heat two pieces of material to the point where they fuse together.

- Laser marking: High power laser diodes and arrays are used to mark a wide variety of materials, including metal, plastic, and paper. Laser marking is a process that uses a laser beam to create a permanent mark on a material.

- Material processing: High power laser diodes and arrays are used to process a wide variety of materials, including metal, plastic, and glass. Laser processing is a general term that encompasses a variety of applications, such as cutting, welding, marking, and engraving.

- Medical applications: High power laser diodes and arrays are used in medical applications, such as laser surgery and laser therapy. Laser surgery is a minimally invasive surgical procedure that uses a laser beam to cut or vaporize tissue. Laser therapy is a non-surgical treatment that uses a laser beam to stimulate tissue repair or relieve pain.

Comparison of High Power Laser Diodes and Arrays

- Power output: High power laser diode arrays have a higher power output than high power laser diodes. This is because laser diode arrays consist of multiple diodes, which can be combined to produce a higher power output.

- Cost: High power laser diodes are typically less expensive than high power laser diode arrays. This is because laser diode arrays are more complex to manufacture.

- Pulsed vs. continuous wave: High power laser diodes and arrays can be operated in either pulsed mode or continuous wave mode. Pulsed mode is typically used for applications where a high peak power is needed, such as laser cutting and laser welding. Continuous wave mode is typically used for applications where a high average power is needed, such as laser marking and laser therapy.

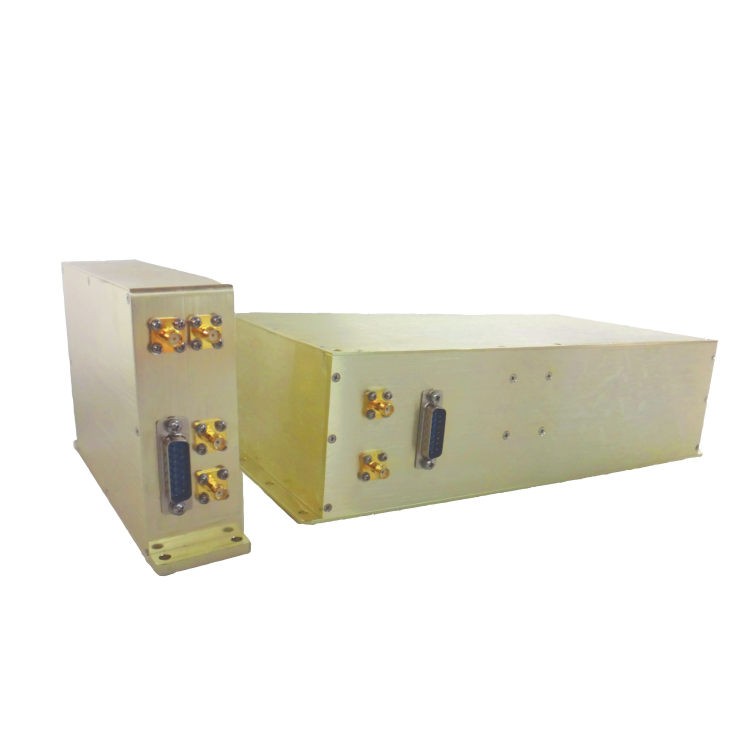

- Cooling: High power laser diodes and arrays can generate a lot of heat. This heat needs to be removed to prevent the diodes from overheating. There are a variety of ways to cool high power laser diodes and arrays, including air cooling, water cooling, and liquid cooling.

Conclusion

High power laser diodes and arrays are both powerful tools that can be used in a variety of applications. The choice of which device to use depends on the specific application. If a high power laser beam is needed, then a high power laser diode array is the best choice. However, if cost is a factor, then a high power laser diode may be the better choice.