Where is the Way Out for InGaAs Photodetectors?

The photoconductive detector is a photodetection device made by utilizing the photoconductive effect of semiconductor materials. With the maturity of electronic science and technology, the application of photodetectors will be more extensive. So how will photodetectors develop in the future? This article will give you the answer quickly.

What is the shortwave infrared band?

The short-wave infrared band is one of the “atmospheric transmission windows”, and the detector can obtain more radiation energy from the target when it works in this band. In addition, the short-wave infrared detection imaging of near-room temperature targets is similar to the reflective imaging of visible light. On the one hand, it has the detail resolution ability lacking in mid-and long-wave infrared detection, and on the other hand, it can penetrate smoke for imaging and other visible light detection does not have the ability.

With the wide application of short-wave infrared detectors in military and civilian fields, higher requirements are put forward for the performance and cost of short-wave infrared detectors.

InGaAs Photodetectors – The Best Photodetectors

At present, the materials used to manufacture short-wave infrared detectors mainly include HgCdTe, InGaAs, PbS, PtSi, and so on.

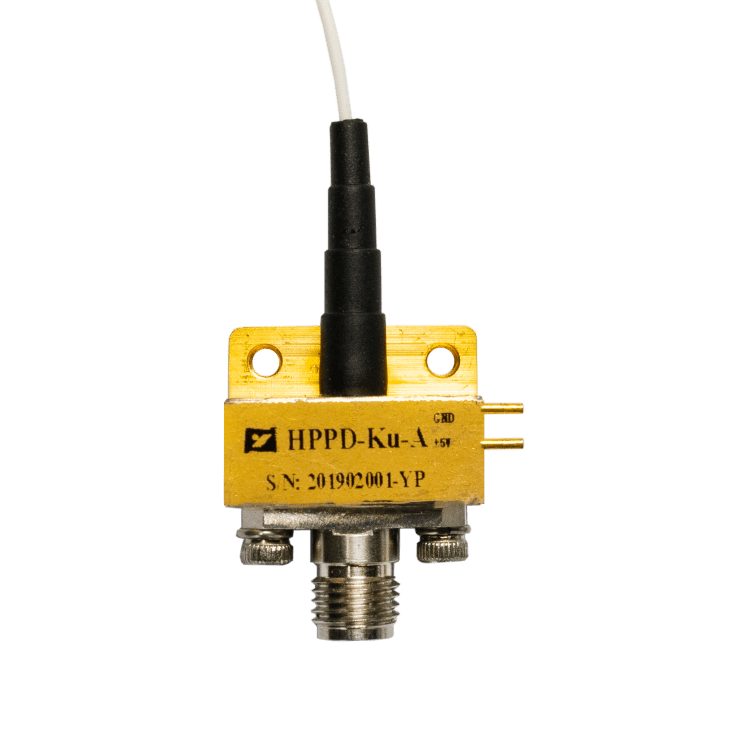

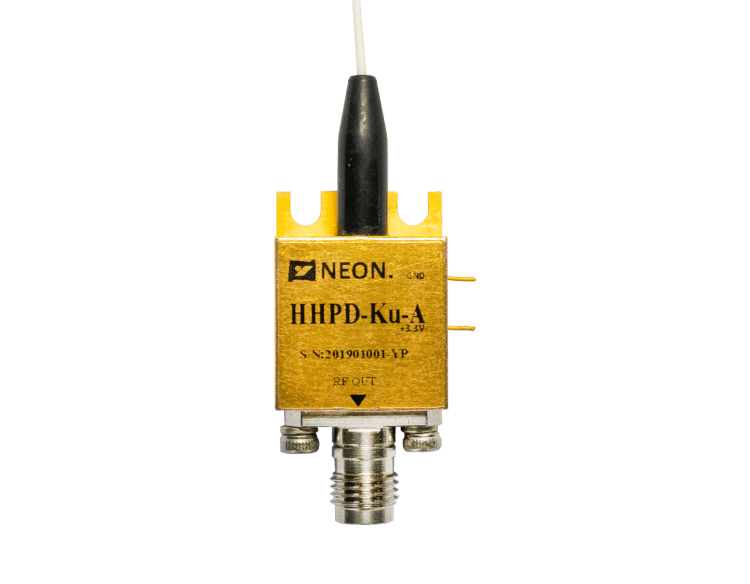

With the continuous maturity of InGaAs material growth and chip fabrication process, compared with other materials, the detector made of InGaAs material has a quantum efficiency as high as about 70%~90% and about 8000 cm 2 /(V s) at room temperature. The high mobility, as well as the application advantages of high sensitivity, high-speed response, and low cost, are the best choice for short-wave infrared detectors.

To further extend the wavelength, improve the resolution, and reduce the cost, short-wave infrared detectors based on new materials and processes such as class II superlattices, colloidal quantum dots, and silicon-based materials have been developed.

The world’s leading manufacturers such as Sensors Unlimited Incorporation in the United States, FLIR, Lynred in France, New Imaging Technologies, Semi-Conductor Devices in Israel, Xenics in Belgium, Sony in Japan, and Hamamatsu are all looking for more possibilities for short-wave infrared detectors.

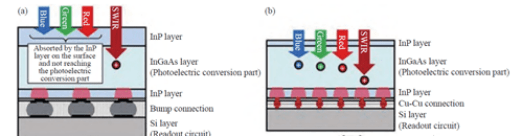

However, the development of InGaAs short-wave infrared focal plane detectors has now entered a bottleneck period. It is difficult to further reduce the cost and improve the resolution in a short period by using the technology of indium column interconnection.

With the continuous emergence of new materials with excellent performance, finding lower-cost alternative materials and improving the manufacturing process have become the key to the development of short-wave infrared detectors.

Colloidal quantum dots (CQD) short-wave infrared detectors do not require complex epitaxy techniques. Through solution processing techniques such as spin coating, CQDs can be grown on CMOS readout circuits at room temperature, and the production efficiency is much higher than other short-wave infrared detectors.

T2SL short-wave infrared detectors have made remarkable progress in material and device structure design, material epitaxial growth technology, focal plane device preparation, readout circuit design technology, etc. The preferred material for the device.

The GeSi detection chip monolithic integration technology, which is fully compatible with Si CMOS technology, solves the problem that the current short-wave infrared imaging pixels can only be manufactured on a wafer production line below 6 inches. It will bring significant cost advantages and further promote the application of short-wave infrared technology in machine vision, semiconductor process inspection, industrial quality control, lidar, and other application scenarios.

Why are InGaAs detectors believed?

InGaAs detectors have become the first choice for short-wave infrared detectors due to their excellent performance, but their performance is close to the limit, and it encounters bottlenecks in further reducing pixel pitch, improving resolution, and expanding array specifications. The high cost leads to problems such as limited applications in the civilian field.

The future development of short-wave infrared detectors will focus on the following aspects:

(1) Expand the wavelength short-wave infrared detector.

(2) Fabrication of short-wave infrared detectors using low-dimensional materials.

(3) Gex and SiX short-wave infrared technology compatible with Si-based CMOS technology will become a major research hotspot.

(4) With the help of technologies such as single-pixel imaging to realize low-cost short-wave infrared cameras, combined with computational imaging, deep learning, and other technologies, low-cost and high-resolution short-wave infrared imaging can be realized.

Short-wave infrared detectors have broad application requirements in both military and civilian fields. The former focuses on products that require higher sensitivity, higher pixel density, and larger area arrays. However, applications in the civilian field require products with low cost and simple integration.

We should strengthen innovation, optimize the preparation process, accelerate the research and development of new materials, and develop short-wave infrared detectors with superior performance and strong competitiveness according to the market demand for both military and civilian use.